Z section Purlins are made from standardised galvanized steel using a rolling process.

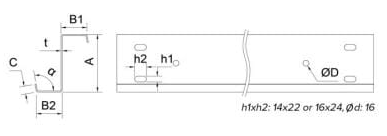

The flanges of Fascon Z-Section Purlins are one broad and one narrow. They are designed to fit precisely and are used to overlap the interior supports to create structurally continuous lines of purlins down the whole length of the building.

Structural continuity increases rigidity, but lapping doubles the thickness of the purlin over supports where bending action is greatest. This conserves 30–50% of steel compared to C Section Purlins.

Z Section: When greater purlin strength is required Purlins with the same depth but differing thicknesses can be lapped as required. Manufacturing facilities and grain or coal processing facilities are examples of structural applications.

A certified steel fabricator must bolt purlins to the primary frame using cleats welded to the rafters or columns. The AISC Standardised Stuctural Connections have standardized the cleats and accompanying hole geometry. Typically, M12 Grade 4.6 bolts require a close tightening for an effective connection.

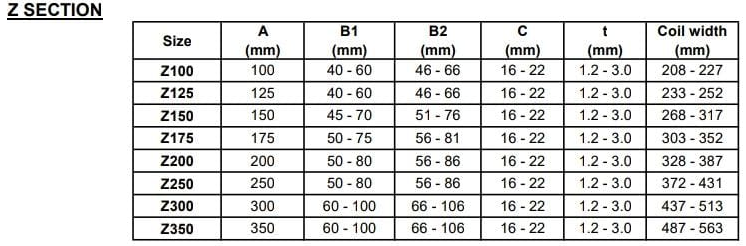

To accommodate slight differences in frame alignment, galvanized steel purlins typically feature relatively large clearance holes – 18mm x 22mm slots for better flexibility. These ample clearances simplify assembly without compromising structural performance.

Additional holes are added when Z purlins are lapped to ensure structural continuity.

Purlins are designed for M12 bolts, hence M16 should not be utilized in these situations. On some of the thicker gauges of lapped Z-section purlins, the holes overlap sufficiently to impede assembly with M16 bolts unless they are pushed.

To reduce the propensity for sections to rotate between supports or bridgings, purlins must be positioned with the top flange facing up the slope from the cleat. Z-Sections must be installed with the web on the low side of the cleat and the upper flange above it.